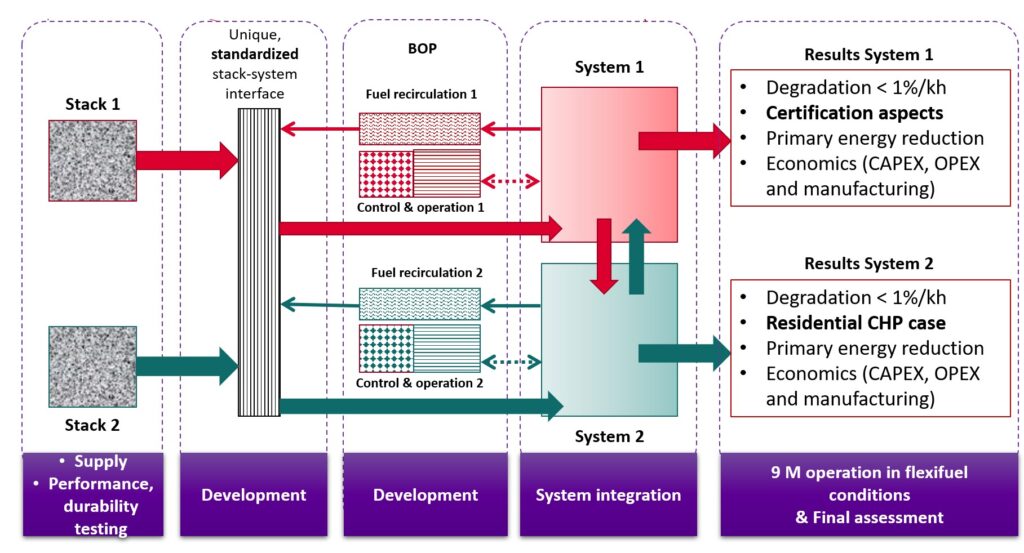

SO-FREE has been conceived to realize a truly flexible SOFC platform, addressing the 5 kWe power class, that allows to integrate multiple SOFC stack technologies within any CHP system, fed with any fuel mixture ranging from natural gas to biogas to pure hydrogen. Two stack technologies are considered in order to cover the full spectrum ranging from the lowest-temperature anode-supported stacks operating at 650°C to electrolyte-supported stacks running at 850°C. The ambition of SO-FREE is to achieve full interchangeability of stacks in different systems, in pursuit of a barrier-free market for SOFC stack and system manufacturers alike, by standardising the stack module-system interface. Main BoP development aspects will focus on the anode gas recirculation and thermal management for the wide operating range, developing necessary controls to achieve fully autonomous regulation of the system as a function of the fuel composition fed.

Finally, the two systems running on flexible fuel compositions will be demonstrated, each for at least 9 months and clocking 6000 hours stack running time. One system will be operated in pre-certification mode addressing all applicable requirements for the prototype in order to formulate a pathway for successive CE conformity and certification. The other system will be operated in end-use application (selected by PGE), in order to identify real-world response and measure ultimate performance, both in terms of stack degradation and end user satisfaction.